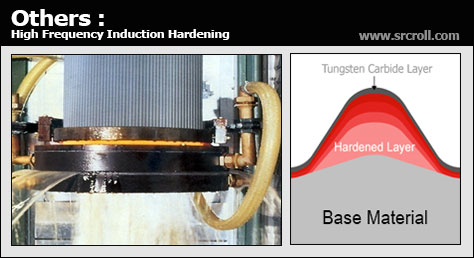

Hardening Method

In order to build durable corrugating rolls it is important to increase surface hardness while keeping the roll less brittle. Most common method to increase the hardness of raw material is high frequency induction hardening after flute forming. Although this method is easier and cheaper, it has disadvantages – shallow hardened layer with uneven hardness distribution. Thereby the rolls are brittle.

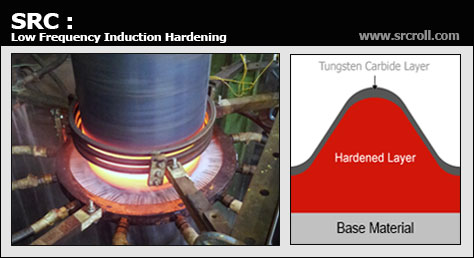

SRC takes different approach to build more durable rolls. We do low frequency induction hardening for deeper hardened layer with uniform hardness distribution. In addition the raw material is hardened before flute forming to reduce cracks or break-up of flutes.

|

|

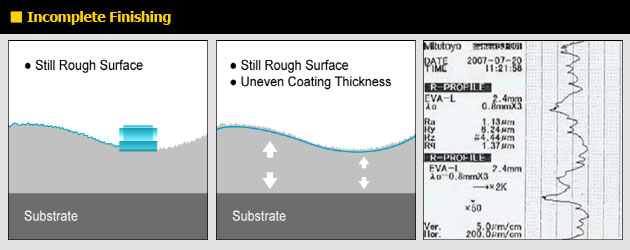

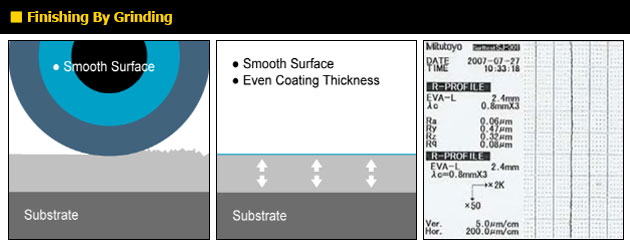

Finishing by Grinding

In order to produce best quality board with maximum speed, flute profile should be accurately ground, and the surface of corrugating roll should be very smooth. Most common way of finishing corrugating rolls are polishing. The considerably big deviation from the designed flute profile due to finishing by polishing can lead to low speed or bad quality board. In addition the high coefficient of friction after polishing increases web tension and causes fractured board.